Gyratory Sieve

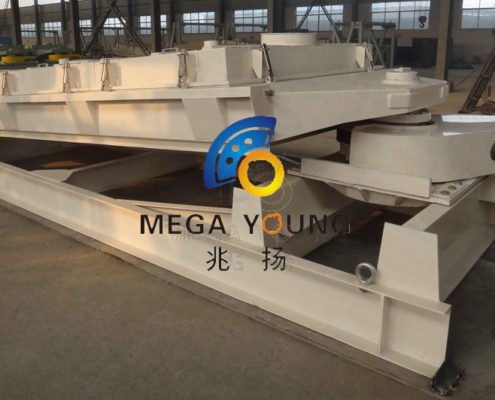

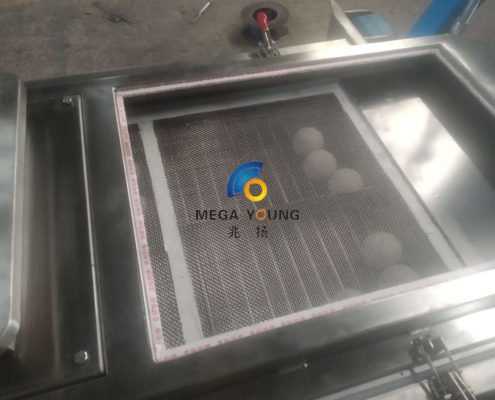

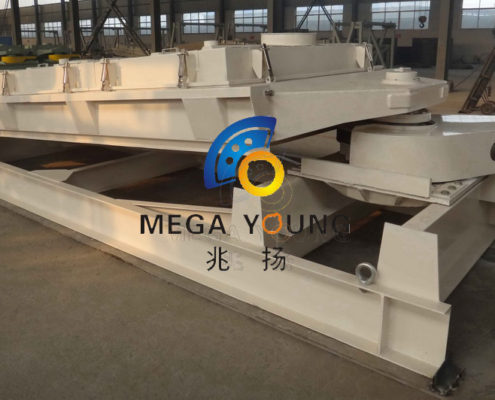

Gyratory sieve is also called square gyratory screen or gyratory sifter, we could supply rectangular gyratory sieve and round gyratory vibrating sieve.

MH Gyratory Sieve

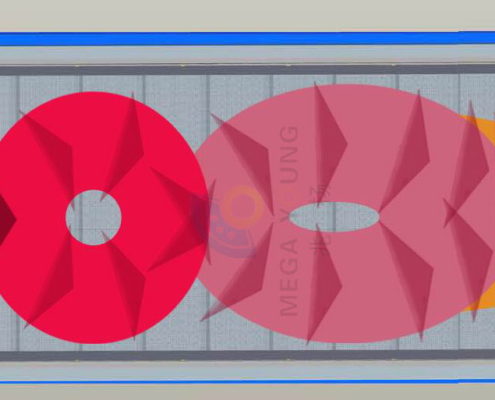

Working Principle of Gyratory Sieve:

The total gyratory movement of the square gyratory sieve can rapidly spread, stratify and separate the material. The unique gyratory motion can quickly spread the material across the full width of screen at the feed end, driving the particles move forward contact with the screen surface. The large horizontal amplitude can improve the sieving effect of the near-size particles, and can improve the material handling capacity of the machine.

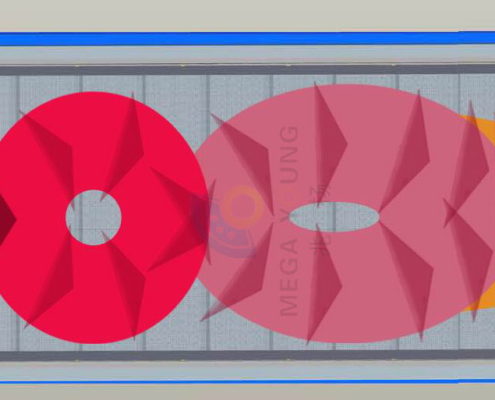

Gyratory Reciprocating Motionpath

Application of Gyratory Sieve

1. Chemical industry: resin powder, paint, washing powder, fine powder, paint, soda ash, lemon powder, rubber, plastic and so on.

2. Abrasive, ceramic industry: alumina, quartz sand, mud, spray soil particles.

3. Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar and so on.

4. Paper industry: coating coatings, white mud, black and white liquid, waste liquid, paper liquid, waste water recovery.

5. Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder.

Single Layer sieve